Testo Measuring and Testing Devices

Thermal Imagers

Description

Thermal imaging cameras can go by many names, including thermographic cameras, thermal imaging scanners, infrared cameras and thermal imagers.

Despite the variations in name, the intent of these instruments is the same: to detect differences in temperature in a given area and provide a visual representation of those variations. The key distinguishing element between a traditional camera and a thermal imager is the spectrum of light it captures.

Traditional cameras record images using the spectrum of visible light, while infrared cameras only capture infrared radiation. Because infrared is outside the range of visible light for humans, thermal imaging cameras extend visibility beyond natural means.

Thermal imaging cameras are so effective in large part because everything above the temperature of absolute zero emits infrared radiation, as Tech Briefs explained. Modern thermal imaging instruments have the sensitivity to effectively represent differences in temperature in a visual format that makes the situation clear to users.

With 8 varying Imaging Kits available – Talk to our Team about your requirements Today – Choose the Model that works best for you + your business model.

| 29803 |

Super Resolution Technology - Building + Industrial

SuperResolution technology is always sought when you need the greatest possible detail in the images for your professional thermographic analysis. The thermal imager's infrared images have a considerably higher resolution and greater detail. The important thing is that: SuperResolution technology always records genuine temperature measuring values – there are no artificial intermediate values projected! This means that SuperResolution technology offers the possibility - without using larger, more expensive detectors - of recording more temperature measuring values with the thermal imager.

Process Analysis Package

The optional process analysis package includes on the one hand, the new feature of sequence storage in the imager. This allows you to record and save temperature developments at freely selectable intervals directly in the thermal imager testo 890 – wirelessly and without a PC. On the other hand, the package contains the fully radiometric video recording. It offers you the possibility of analyzing saved videos and sequences in the clearly structured software Testo IRSoft. In addition to this, you can also stream radiometric measurement data by online measurement into the analysis software at up to 25 Hz, and record sequences. This means that all changes are immediately visible in the thermal image, even in fast-moving processes. In addition to this, the video measurement offers you the possibility of controlling the imager remotely, and of saving individual images either as a thermal image of a JPEG-file.

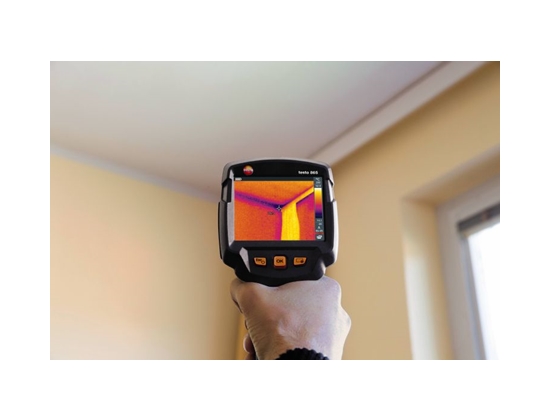

Humidity Image

Moisture in the interiors of buildings often leads to extensive problems: construction defects and incorrect user behaviour can result in mould formation. Testo's patent-pending “humidity image” displays the relative surface humidity for each individual measuring value in the image. This means you can measure any increased humidity and detect the first signs of mould damage, before this is actually visible to the naked eye. The thermal imager's temperature measurement here serves as a basis for calculating the relative surface humidity. The humidity pallet on Testo thermal imagers then uses the traffic light principle to represent the different risk zones: Green = no risk | Amber = caution, mould formation possible | Red = WARNING! Risk of mould

Scale Assist

Structural defects and thermal bridges can easily be assessed | The thermal image scale with automatic optimal setting prevents misinterpretations | Unwanted extreme temperatures are automatically filtered out | Only structural defects that are actually present are presented as such | Infrared images can be reliably compared, for example with before and after shots.

Fever Detection

Disease Prevention | Identify persons with increased body temperature quickly and easily.

Panorama Image Assistant

Taking thermal images of very large objects at close range is often tricky. This is where the Testo panorama image assistant can help. It allows several individual images to be collated into one overall view for easy analysis.

Site Recognition

Efficient inspection routes | Particularly practical for preventive maintenance. The testo SiteRecognition technology guarantees fully automatic measuring location recognition, as well as storage and management of thermal images resulting from inspections. This rules out any mix-ups, prevents errors during evaluation and saves time by eliminating the need for manual image assignment on the PC.

e-Assist

Even more precise thermal images | Emissivity and reflected temperature are automatically set.

IRSoft

Analysis Software | Independent and really easy creation of professional thermographic reports.

Thermography App

Smart, networked work | Your smartphone/tablet becomes a remote control, second display and report centre.