HEPA Filters

AstroCel® III HEPA Filters

Description

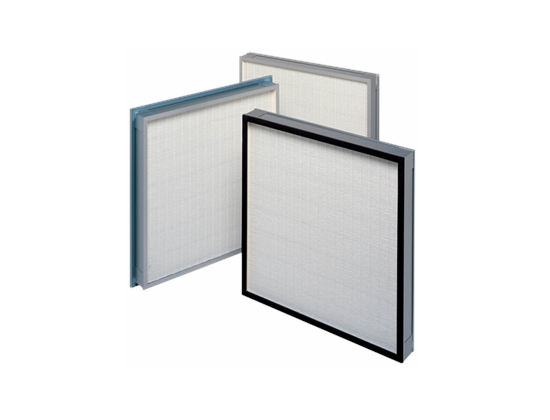

AstroCel® III HEPA Filters

HIGH-FLOW, LOW-PRESSURE-DROP HEPA FILTER

Product Overview

- Ideal for demanding operating conditions in critical applications

- Longer service life — 436 square feet of media — means fewer change-outs

- Low energy consumption and lower operating costs

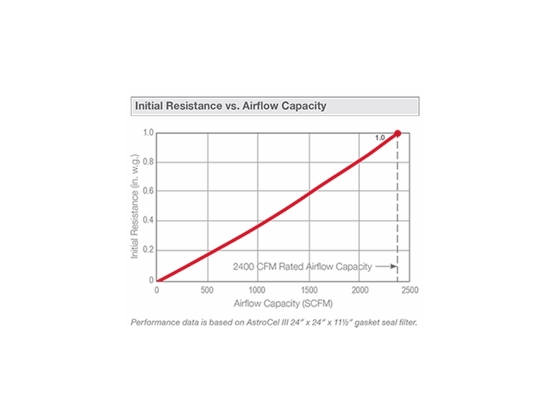

- High-capacity operation with minimal resistance to airflow

- Chemical-resistant anodized aluminum frame provides superior strength

- One-piece polyurethane gasket seal and gel seal designs available

Typical Applications

AstroCel III HEPA filters are ideal for applications operating with higher airflows, up to 600 FPM, and requiring ultra-low pressure drop:

- Semiconductor and electronics manufacturing

- Pharmaceutical processing

- Photo-film manufacturing/processing

- Hospitals, laboratories, and optical facilities

- Food processing

Longer Service Life and Lower Energy Consumption

Multiple mini-pleat media packs, assembled into a series of V-banks, permit substantially more media to be contained in the filter — double the media typically found in most HEPA filters. Maximum effective media area provides greater airflow capacity, low resistance, high dust holding capacity, and unusually long service life. The V-bank configuration provides greater airflow capacity and longer service life, while lowering operating costs.

Media Configuration Reduces Operating Costs

AstroCel III filter media is made from sub-micron glass fibers formed into a high-density paper. Glass filament separators are used to form the media into mini-pleat panels that withstand high-velocity airflow. The V-bank configuration optimizes media performance for high airflow at very low resistance. Mini-pleat packs are sealed to the frame with two-component polyurethane to increase rigidity and prevent bypass leakage. Construction-extruded aluminum frame components resist chemical corrosion, provide high strength, and are lighter. Cell sides are made from a single extrusion to maximize construction integrity. A gasket seal frame is also available with galvanized sheet-metal cell sides.