HEPA Filter

MEGAcel® II ePTFE HEPA Filter

Description

MEGAcel® II ePTFE

MINI-PLEAT EPTFE MEMBRANE ULPA FILTER

Product Overview

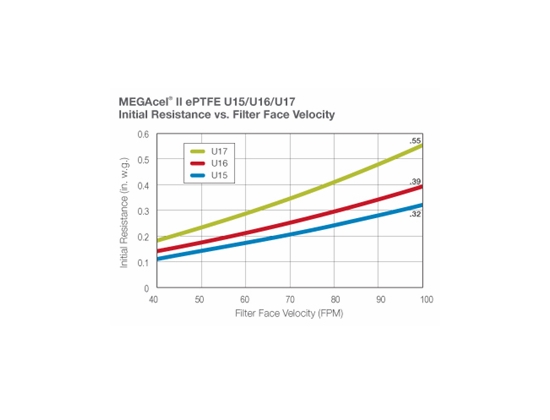

- Lowest initial resistance available

- Negligible off-gassing properties (boron-free)

- AAF Flanders’ high tensile strength ePTFE media is up to 6 times stronger than microglass

- Highly resistant to corrosive environments (acids, alkalis, and organic substances)

- Gasket seal, gel seal and knife-edge designs available

- Lightweight anodized aluminum frame

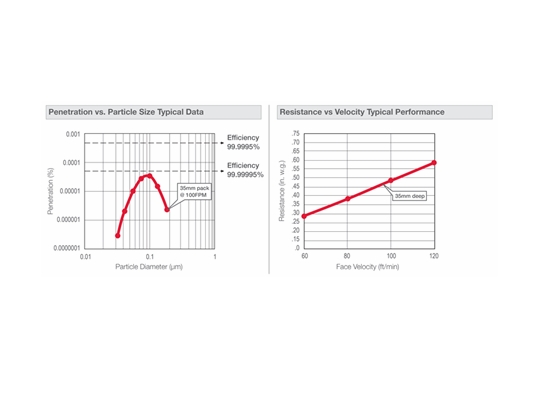

- Efficiencies up to 99.999995% at MPPS available

- Meets I300I specifications and is UL 900 and ULC S111 classified

Typical Applications Include – Microelectronics | Healthcare | Pharmaceutical | Food Processing Laboratory | Semiconductor Manufacturing

Energy Conservation

AAF Flanders ePTFE ULPA filtration technology provides initial resistances at a minimum of 30% lower than conventional micro fiberglass media, resulting in unmatched reductions in fan energy consumption. AAF Flanders’ pleating method, which uses intermittent polyamide separators, allows more open and effective media area, minimizing pleat pack resistance.

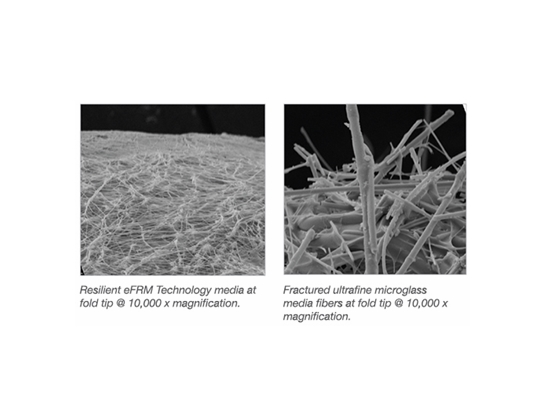

A Perfect Filter Media

Compared to micro fiberglass media, AAF Flanders’ ePTFE media provides superior benefits, including inert chemical properties and reduced resistance. Achieved through a more uniform fiber distribution, smaller fiber distribution, smaller fiber diameter, and smaller pore size, ePTFE media generates substantial energy savings while delivering the required filtration performance.

Sturdy Construction

Tooling environments often produce harmful and corrosive by-products. The MEGAcel® II ePTFE filter is extremely resistant to these harsh conditions, and also offers superior efficiency and pressure drop characteristics. Manufactured with a proprietary, high-quality ePTFE media, the MEGAcel® II ePTFE filter is hydrophobic and meets the requirements of UL900. The media pack is permanently attached to an anodized extruded aluminum frame using a urethane adhesive.

Chemical Advantages of AAF ePTFE Media - Negligible Off-Gassing

AAF Flanders' ePTFE media is naturally boron-free and the materials of construction have been chosen to meet the most stringent of off-gassing requirements. The off-gassing impurities are significantly reduced compared to micro fiberglass.

Chemical Advantages of AAF ePTFE Media - High Corrosion Resistance

AAF Flanders' ePTFE media is chemically inert and resistant to highly corrosive agents, including alkaline, acid, and organic substances- all of which can be found in semiconductor manufacturing processes.

Chemical Advantages of AAF ePTFE Media - Superior Water Resistance

AAF Flanders' ePTFE media is hydrophobic and provides superior water resistance in comparison with micro fiberglass and low boron micro fiberglass media.

Media Type

ePTFE

Frame Material

Anodized extruded aluminum

Separator Style

Hot Melt

Gasket Material

Polyurethane (PU)

Max Operating Temperature

158˚F (70˚C)