HEPA Filter

MEGAcel® II eFRM HEPA Filter

Designed specifically for the unique requirements and challenges of the aseptic pharmaceutical manufacturing industry, the MEGAcel II mini-pleat HEPA filter has superior durability, polyalphaolefin (PAO) compatibility, high particulate filtration efficiency, and the lowest pressure drop.

Typical Applications include – Pharmaceutical | Life Sciences | Biosafety | Healthcare | Pill Encapsulation

Description

MEGAcel® II eFRM HEPA Filter

MINI-PLEAT EFRM HEPA FILTERS

Product Overview

- Patent pending, polymer-based, dual-density, expanded Fluororesin Membrane- eFRM

- Minimum 99.99% at 0.3 μm, H13, and 99.995% at MPPS, H14

- Polyalphaolefin (PAO) compatible

- Lowest pressure drop mini-pleat HEPA filter available for pharma, life sciences

- Lightweight anodized aluminum frame

- Gel, gasket, or knife-edge seal available

- Thermoplastic hot-melt separators

Typical Applications include – Pharmaceutical | Life Sciences | Biosafety | Healthcare | Pill Encapsulation

Designed specifically for the unique requirements and challenges of the pharmaceutical industry, the MEGAcel II eFRM mini-pleat HEPA filter has the proven durability, polyalphaolefin (PAO) compatibility, high particulate filtration efficiency, and lowest pressure drop to meet the demands of pharmaceutical manufacturing. It is the best choice for the most demanding applications, saving both time and money, while reducing contamination risk and invasive unscheduled downtime. With the lowest Total Cost of Ownership of all mini-pleat HEPA filters, the MEGAcel II eFRM will help protect your environment, reduce your business risk, and optimize your clean air related spending.

Proven Reliability With Exceptional Performance

- MEGAcel II eFRM is designed to increase cleanroom uptime and reduce the risks associated with pharmaceutical manufacturing

- Pharmaceutical grade eFRM media is proven to be more durable than microglass, delivering superior performance

- Industry’s first and only eFRM media to be Polyalphaolefin (PAO) compatible, with equivalent PAO holding capacity when compared to microglass media

- Superior durability and tensile strength, 84 times the pleated strength of microglass

- Chemical-resistant capabilities reduce media degradation in highly corrosive environments

- Exceptional water resistance compared to ultrafine microglass

- Extremely low off-gassing of chemical components, resulting in the highest quality clean air available

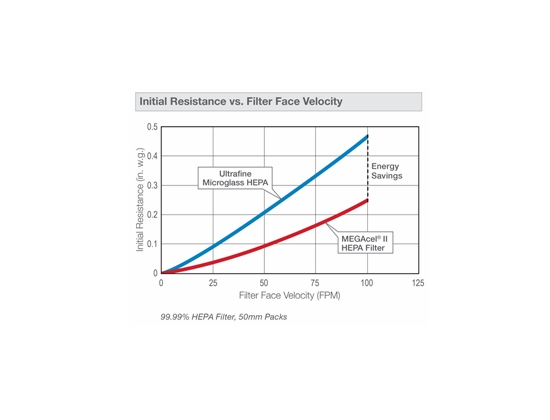

- Lowest pressure drop mini-pleat HEPA filter available, reducing energy consumption for significant savings

- MEGAcel II eFRM media is manufactured, tested, and packaged in ISO 7 clean facilities to ensure the highest purity, quality, and consistency

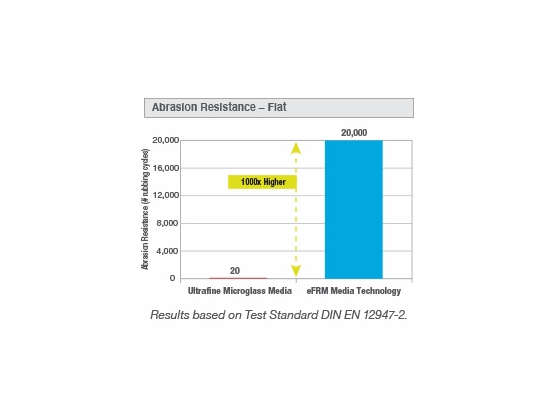

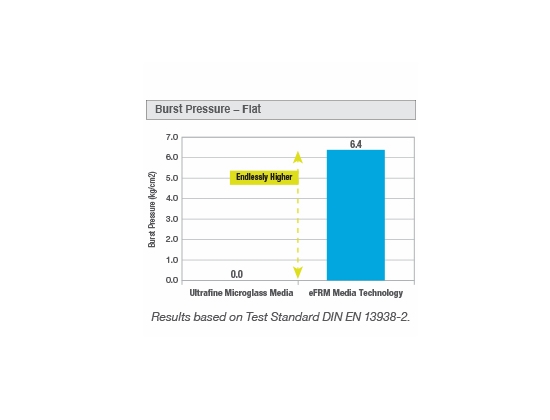

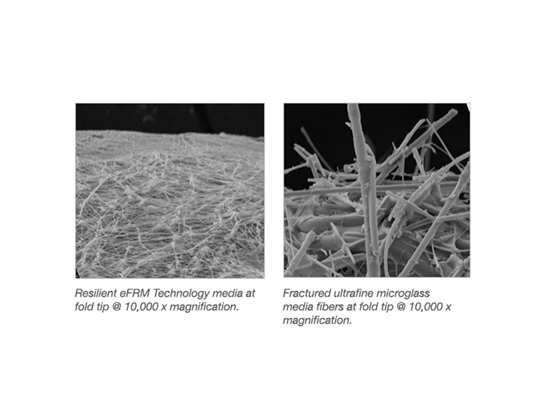

Industry-Leading Durability

Independent tests have shown that MEGAcel II HEPA filters with eFRM Media Technology have superior mechanical strength over filters with traditional ultrafine microglass media.

The superior mechanical strength is demonstrated by a high tensile strength, burst pressure, and abrasion resistance. eFRM Media Technology retains its integrity with a high aversion to any potential damage, such as mishaps in handling or installation. This mitigates the risk of filter media failure and additional incurred validation and repair expenses. As a result, there is a decreased risk of contaminants entering cleanroom environments. Protection of sterile products and cleanroom personnel is optimized. Improvement in quality risk management systems of critical applications ensures a consistent supply of quality products and a reduction of failure rates.

Reduce Operational Risk

The pharmaceutical industry estimates that 77% of production downtime can be attributed to failures of equipment and environmental problems. This downtime can be caused by HEPA filters failing. Traditional microglass HEPA filters typically fail due to some form of contact combined with the poor mechanical strength of the filter. The actions required when these failures occur include repairing/replacing the HEPA filter, certifying the repair or new installation, investigating potentially contaminated product, and generation of a risk assessment report. Effectively managing the risk and costs associated with successful operation requires utilizing HEPA filters with dramatically higher tensile strength that is highly resistant to chemical degradation, thereby eliminating premature leaking and failure.

Increase Uptime

While FDA Testing Guidance requires critical room leak-testing certification twice a year, non-critical rooms require testing only once a year. With the extremely high tensile strength and durability of the eFRM pleated filter media, 84 times stronger than microglass, ISO 7 and 8 areas could be tested annually. Increasing time between certifications results in less PAO exposure to the gel seal (gel degradation), lower labor costs, and increased production time.

MEGAcel II eFRM - First and Only PAO Compliant eFRM Media HEPA Filter

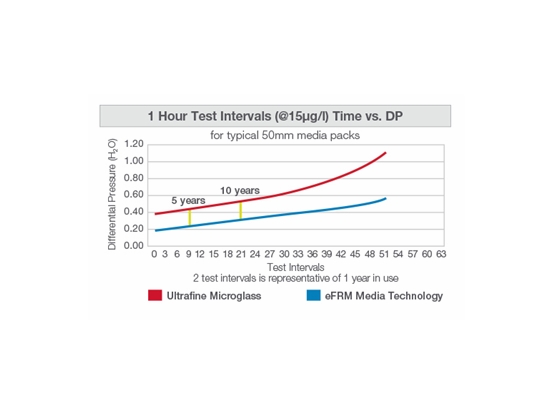

The purpose of installed HEPA filter integrity testing, also called in-situ testing, is to confirm a flawless performance during normal operation. With AAF Flanders’ new eFRM Media Technology, MEGAcel II filters can be scan tested with the industry standard photometer at the standard aerosol concentrations, as well as the low-aerosol concentration Discrete Particle Counter (DPC) method. The MEGAcel II filter contains dual-density eFRM Media Technology media specifically developed to retain equivalent amounts of PAO aerosol with equivalent or lower pressure drop increases as ultrafine microglass. The dual-density eFRM layers allow for the in-depth capture of progressively smaller solid particles. Independent laboratory studies have shown that MEGAcel II eFRM Media Technology have compatible PAO holding capacity as compared to traditional ultrafine microglass HEPA media, while providing significant reduction in system resistance, which equates to energy savings, as seen in the results below.

Enhanced Chemical Tolerance - High Corrosion Resistance

eFRM Media Technology is proven to be resistant in highly corrosive environments, and will withstand attacks from common decontamination chemicals. Both components of the eFRM Media Technology, the membrane and non-woven layers, are stable against exposure at the prescribed time and concentration for the above disinfectant agents.

Enhanced Chemical Tolerance - Superior Water Resistance

Based on AAF Flanders’ test lab results, eFRM Media Technology provides superior water resistance in comparison with ultrafine microglass, reducing damage risk.

Enhanced Chemical Tolerance - Negligible Off-Gassing

eFRM Media Technology has extremely low off-gassing of chemical components, resulting in the highest quality clean air available.

Media Type

eFRM

Frame Material

Anodized extruded aluminum

Max Operating Temperature

158˚F (70˚C)