HEPA Filter

MEGAcel® I eFRM HEPA Filter

Manufactured with AAF Flanders’ eFRM expanded FlouroResin Membrane media and an innovative tapered aluminum separator design, MEGAcel I eFRM filters are the industry’s highest performing HEPA filter. Optimize system efficiency, strength, and integrity, while minimizing operational expenses.

Typical Applications Include – Healthcare | Food Processing | Pharmaceutical | Laboratory | Microelectronics | Semiconductor Manufacturing | Industrial

Description

MEGAcel® I eFRM HEPA Filter

HIGH-PERFORMANCE EFRM MEMBRANE HEPA FILTER

Product Overview

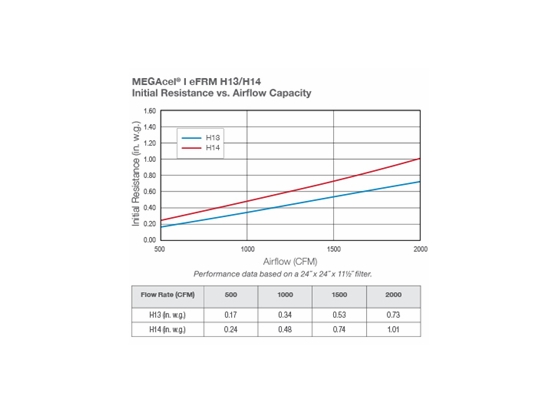

- Lowest initial resistance – Up to 50% lower than glass media alternative

- High tensile strength and chemically inert properties of eFRM reduce risk of media damage and degradation

- Highly resistant to corrosive environments (acids, alkalis, and organic substances)

- Lowest offgassing properties available

- Withstands pressure up to 20 in. w.g. (5,000 Pa)

- Minimum 99.99% at 0.3 μm, H13, and 99.995% at MPPS, H14

- Compatible with Discrete Particle Counter (DPC) and photometric test methods, including high concentration oil-based aerosol testing

Designed to combine maximum efficiency with lowest pressure drop, the MEGAcel I eFRM filter media pack is available in different depths, sizes, and cell side configurations, allowing for a variety of application requirements, including;

Healthcare | Food Processing | Pharmaceutical | Laboratory | Microelectronics | Semiconductor Manufacturing | Industrial

Energy Conservation=Energy Savings

AAF Flanders' eFRM pleat pack resistance is up to 50% lower than conventional micro fiberglass media, a significant factor contributing to a great reduction in fan energy consumption. AAF Flanders' eFRM membrane media, combined with tapered aluminum separators, optimizes pleat pack resistance. With a reduction in fan energy consumption, overall energy savings can be realized.

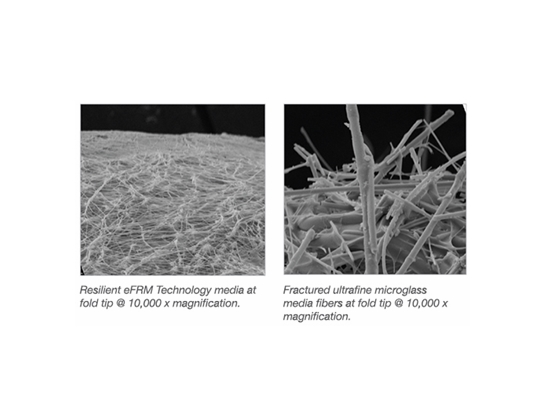

Perfect Filter Media

Compared with micro fiberglass media, eFRM membrane media provides superior benefits, including inert chemical properties, more uniform fiber distribution, smaller fiber diameters, and smaller pore size. As a result, reduced resistance and higher filtration performance provide substantial energy savings.

eFRM Membrane Media Developed by AAF Flanders Engineers

Groundbreaking eFRM technology was engineered by AAF Flanders’ research and design teams. Media production, testing, and packaging are all performed in AAF Flanders’ ultra-modern ISO Certified controlled environment, eliminating the potential for contamination of the filter during manufacturing.

Filter Depth

11 1/2" (292 mm)

Media Type

eFRM

Frame Material

Galvanized Steel | Stainless Steel

Separator Style

Aluminum

Gasket Material

Polyurethane (PU)

Max Operating Temperature

158˚F (70˚C)